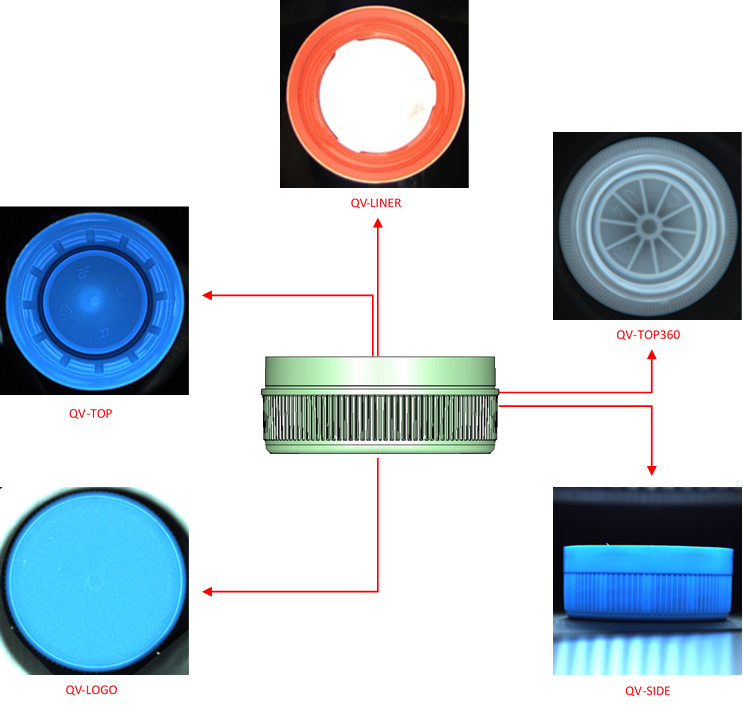

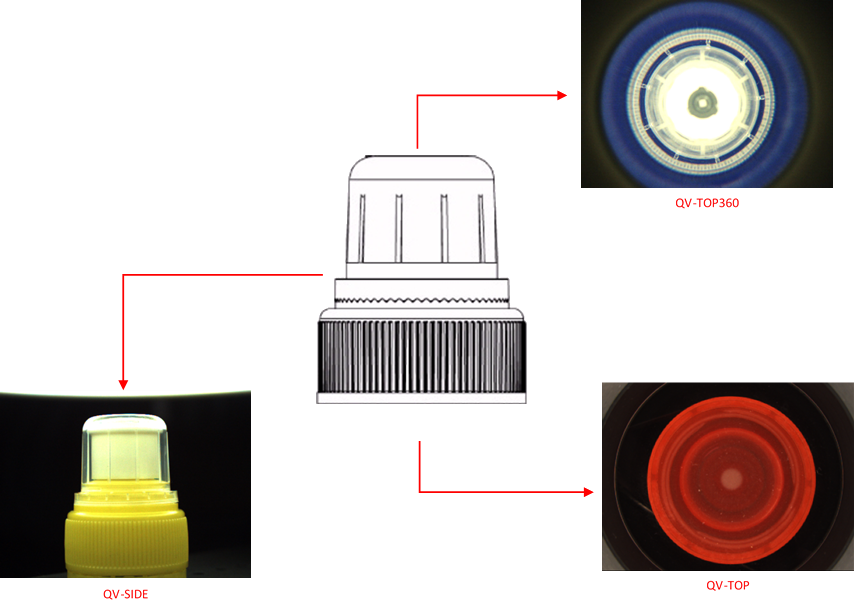

Plastic/Flat

For the inspection of “flat” caps. Typical installation is at the exit of a molding machine, after pieces have been orientated upward facing by a dedicated feeder or after an inserting (lining) machine. The vision system in its “full” configuration is normally installed on a transportation machine composed by a star-wheel and a vacuum conveyor belt, but other solutions are possible, depending on the desired inspections.